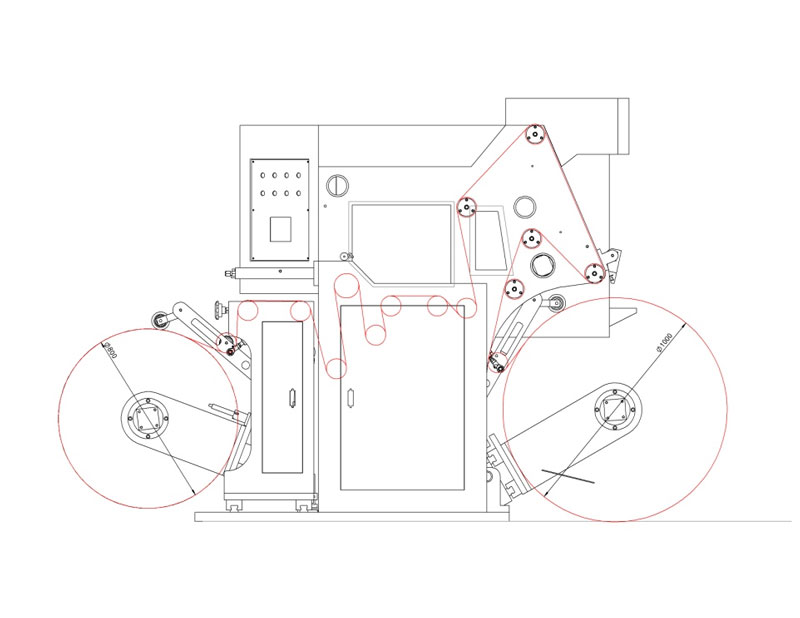

JP-1300 Automatic High Speed Inspection and Rewinding Machine

|

Type |

Parameters |

|

Dia. Of Unwinding |

Φ800(MAX) |

|

Dia. Of Rewinding |

Φ800(MAX) |

|

Range of Unwinding width |

400-1300mm |

|

Dia. Of unwinding paper core |

3/6Inch |

|

Dia. Of rewinding paper core |

3/6Inch |

|

Rewinding accuracy |

±0.3mm |

|

Max. inspection speed |

300m/min |

|

Range of Best inspection length |

5-27 cm |

|

LPC Correction accuracy |

≤±0.1mm |

|

Range of tension |

3~30 |

|

Total power |

≈15Kw |

|

Voltage |

AC 380V, three-phase 50HZ |

Product information

Product Description

The JP-1300 automatic high speed inspection and rewinding machine adopts double traction devices to improve the friction between the material and the roller surface, reduce slippage, and ensure the accuracy of meter counting. Servo motor is used to ensure stable tension, high transmission accuracy and stable operation.

Instruction

Unwinding Structure

The Unwinding part adopts Non-axial Air pressure and gets way with Air Chuck, feeding rack is lifted by hydraulic device. LPC transverse follows the edge and the line. Auto tension control, servo motor control, material remainder alarm.

Specification

| Unwinding width (Max.) | 1350mm |

| Unwinding diameter (Max.) | φ800mm |

| Max. Unwinding weight | 1000kg |

| Dia. Unwinding core | 3 inch/6 inch (option) |

| Material remainder alarm | φ200mm(can set) |

| Servo motor | 5 kw |

| Tracing accuracy | ±0.1mm |

Feature

The Unwinding part adopts Non-axial Air pressure and gets way with Air Chuck, feeding rack is lifted by hydraulic device, easy loading.

The ELPC can make sure the edge accurately when slitting, the encoder check the tension, calculating test the roll diameter can make the tension controlling much more scientific and accuracy.

The Deflector roller and the guiding roller

Structure

The deflector structure is manual, adopts the screw and guide rail structure.

One side of the deflector roller is fixed, and the other side is adjusted front and back.

The deflector roll and the guiding roll adopts imported bearing.

Specification

| Diameter of the deflector roller | φ100mm |

| Length of the deflector roller | 1350mm |

| Range of the deflecting | ±20mm |

| Diameter of the guiding roller | φ100mm |

| Length of the guiding roller | 1350mm |

Feature

The deflector roller is suitable for different types of films.

After the dynamic balance, there is no vibration source, reduce the machine noise.

Length counting device

Structure

Roller type length transmitter, contact and rotation with traction roller.

Can set the rewinding length, auto stop when the rewinding length comes to the setting requirements.

Feature

The length counting is accurately, It will alarm when it reaches the setting length, then stops automatically , easy operation.

Traction device

Structure

Driving by the servo motor. Synchronous belt. Active traction roller adopts rubber roller. All the rotator adopts imported bearing.

Specifications

It adopts double traction device, improving friction between material and roller surface, reduce slip phenomenon, ensure the accuracy of the meter counting. After the dynamic balance, there is no vibration source, running stable. It adopts imported bearings, ensure the machine running stable, and reduce the noise. Adopts the servo motors, ensure the tension stable , high transmission accuracy, stable running.

Rewinding

Structure

The Unwinding part adopts Non-axial Air pressure and gets way with Air Chuck, feeding rack is lifted by hydraulic device. Tape tension controlling. Pneumatic pressure roller .Rewinding by servo motors.

Specifications

| Rewinding width (Max.) | 1350mm |

| Rewinding diameter (Max.) | φ800mm |

| Max. Rewinding weight | 1000kg |

| Dia. Rewinding core | 3 inch/6 inch (option) |

| Servo motor | 5 kw |

Features

The Rewinding part adopts Non-axial Air pressure and gets way with Air Chuck, feeding rack is lifted by hydraulic device, easy loading.

The encoder check the tension, calculating test the roll diameter can make the tension controlling much more scientific and accuracy.

Pneumatic pressure device, pressure adjustable, can ensure the rewinding of different material smoothly

Inspection

Structure

It adopts quadruple strobe lamp photoelectric external trigger. Manually set scrap memory point, and find the memory automatically.

Specification

| Length of quadruple strobe lamp | 1250mm |

| Single light spot | 350mm*300mm*150mm |

| Best inspection length range | 5-27cm |

Feature

It can chase the pictures automatically according to the rewinding speed.

Frame

It adopts high strength and low pressure steel wallboard. The wallboard after secondary stress relief, with good stability.

It is made by the imported machining center with high machining accuracy; reserve the installation position of online detection system.

Air system

The machine adopts many pneumatic actuator, it is operated by the panel, carried out by solenoid valve.

in order to make sure of the machine function ,the main pneumatic elements all from Taiwan.

Electric control system

It adopts interface, CPU centralized control, modern techniques.

The interface can show and set the inspection speed, length ,cumulative length, can set the rewinding tension, taper setting.

All the operation can be done at both unwinding and rewinding sides, easy operation.

The machine is also with the function of saving parameters, can save 10 types tension parameters of different materials, easy to read when run the machine, can shorten operation time.

Other: with the trimming function of flat cutter.

Sample

|

|

|

Selected Products

News Center

> Automatic die-cutting machine type

The automatic die-cutting machine is that the paper feeder sends the paper to the designated position of the front gauge and the side gauge through the feeding part,...

> How is the pla paper cup produced by the disposable paper cup manufacturer?

How is the pla paper cup produced by the disposable paper cup manufacturer? It turned out to be done in this way

> The process of making paper cups for hot drinks

The production process of the disposable paper cup cold drink cup is direct printing, die cutting, molding processing, and spraying food wax on the surface of the pa...

> Raw materials for making paper cups

1. In the raw materials for making paper cups, in order to avoid the production of toxic solvents, the national standard stipulates that paper cups should not have p...

GET A QUOTE