970mm Automatic Roll Stamping and Die Cutting Machine

|

Type |

ZJTM-970 |

|

Stamping accuracy |

≤±0.15mm |

|

Max. stamping speed |

110 times/min |

|

Max. stamping pressure |

320 T |

|

Max. stamping width of paper |

940*550mm |

|

Min. stamping width of paper |

400*360mm |

|

Suitable paper weight |

100g-500g |

|

Total power |

32KW |

|

Overall dimension |

8600*2400*2300mm |

|

Weight |

14T |

Product information

Product description

The 970mm automatic roll stamping and die cutting machine adopts high-quality multi-function vector digital display frequency converter, automatic speed regulation; adopts PLC programming control technology, and works accurately.

Brief Introduction

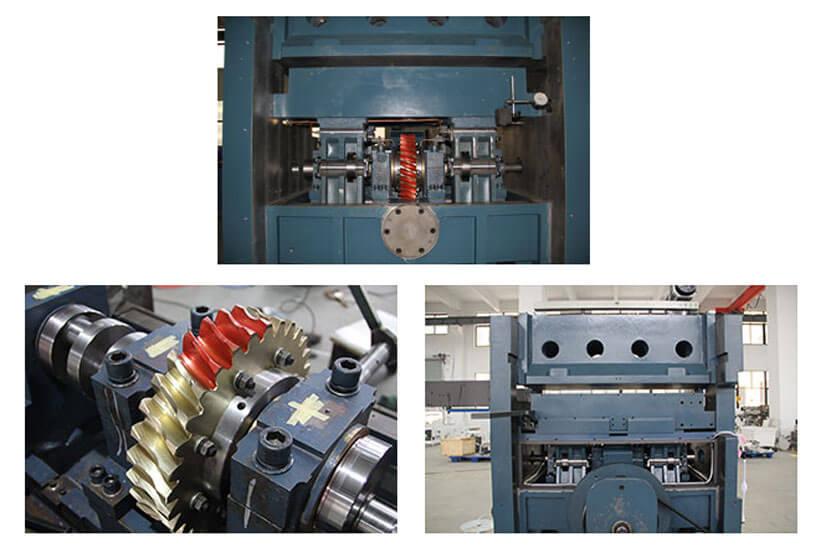

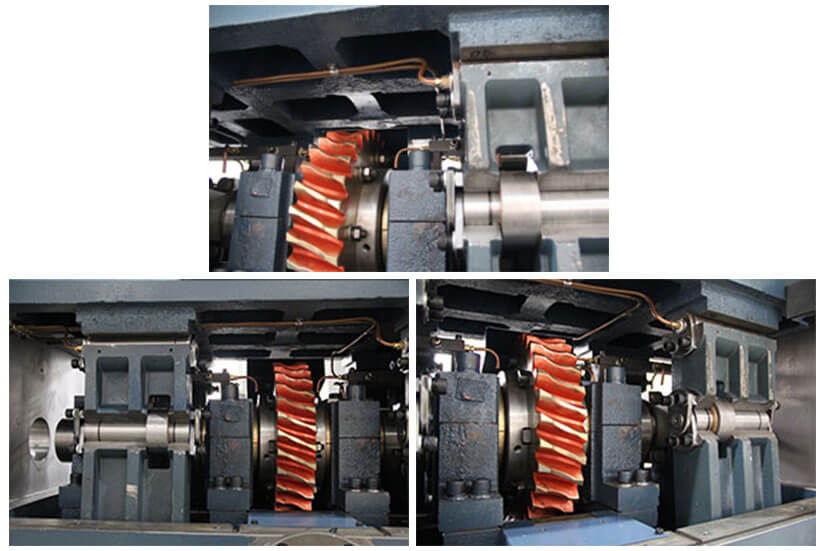

- The main part adopts worm, worm gear, rotating and driving each connecting rods to complete the running. High stability and low mechanical noise.

- The main motor is with high quality multi function vector digital display converter, automatic speed regulation; it adopts PLC programming control technology, working precisely.

- With Touch panel, Chinese –English display, can realize man-machine interaction.

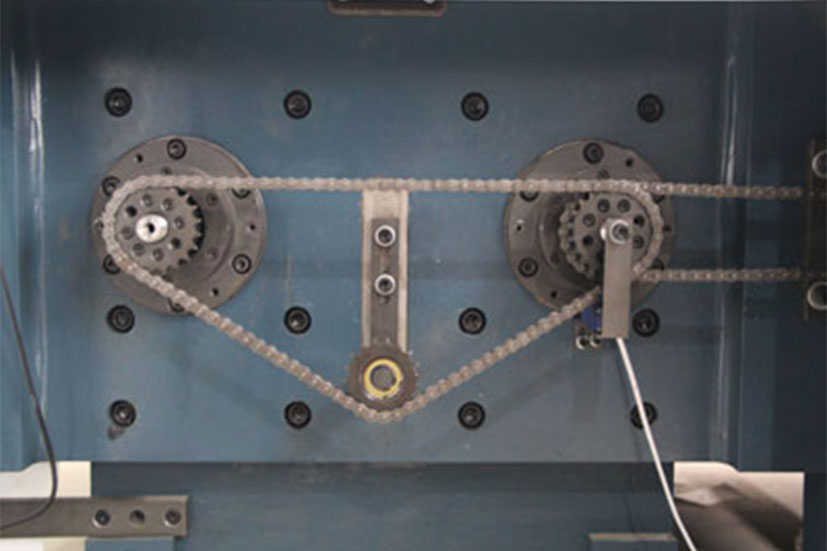

- It adopts Original imported Innovance servo motor and synchronic belt from Germany, make the machine running and transmission stable, accurate positioning, high accuracy.

- There are horizontal and vertical two directions for stamping, fast, accurate and stable.

- Can reduce the costs substantially, and improve the efficiency.

Sample

|

|

|

|

Features & Benefits

Perfect worm wheel and worm transmission system ensures the powerful and steady pressure and makes the cutting accurately while the machine runs with high speed, has features of low noise, smooth running and high cutting pressure. Main base frame, moving frame and top frame are all adopts high strength Ductile Cast Iron QT500-7, which has features of high tensile strength, anti-deformation and anti-fatigable.

Adopts forced lubrication system to ensure main driving oil supply regularly and reduce frication and prolong the machine life, machine will shut down for protection if oil pressure is low. The oil circuit adds a filter to clear the oil and a flow switch to monitor lacking oil.

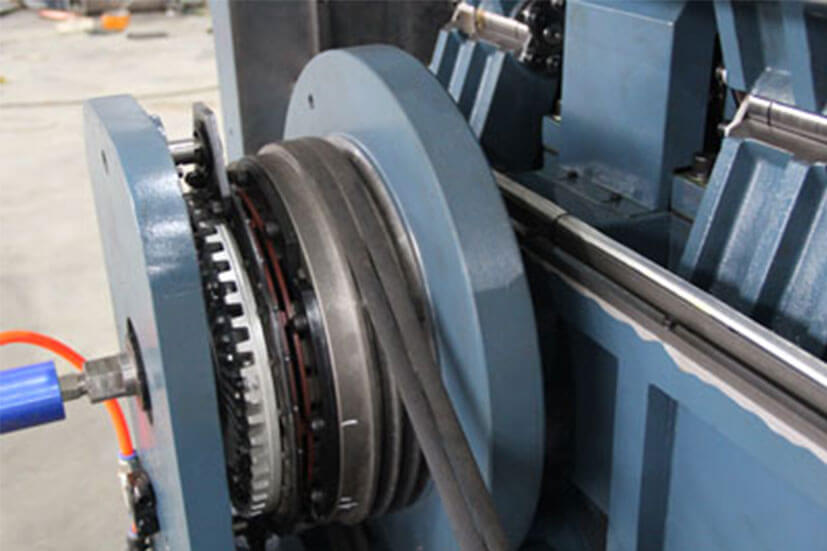

The die-cutting force is provided by a 7.5KW inverter motor driver. It is not only power-saving, but also can realize the stepless speed adjustment, especially when coordinate with the extra large flywheel, which make the die-cutting force strong and steady, and the electricity can be further reduced. Pneumatic clutch brake: through adjust the air pressure to control the driving torque, low noise and high brake performance. The machine will shut down automatically if overload happened, response sensitive and fast.

accurate and fast to achieve die-cutting pressure adjustment. The pressure is automatic adjusted through the motor to control the four feet by HMI. It is very convenient and accurate.

Selected Products

News Center

> Automatic die-cutting machine type

The automatic die-cutting machine is that the paper feeder sends the paper to the designated position of the front gauge and the side gauge through the feeding part,...

> How is the pla paper cup produced by the disposable paper cup manufacturer?

How is the pla paper cup produced by the disposable paper cup manufacturer? It turned out to be done in this way

> The process of making paper cups for hot drinks

The production process of the disposable paper cup cold drink cup is direct printing, die cutting, molding processing, and spraying food wax on the surface of the pa...

> Raw materials for making paper cups

1. In the raw materials for making paper cups, in order to avoid the production of toxic solvents, the national standard stipulates that paper cups should not have p...

GET A QUOTE