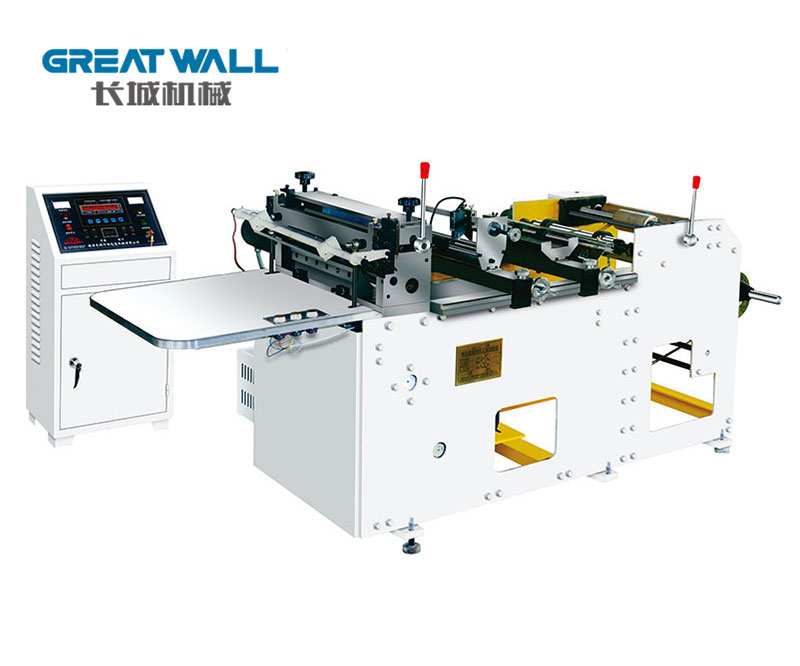

QD-350 High Speed Cutting Machine

| effective width | 350mm |

| working frequency | 500r/min(according to the material) |

| range of length | 1~999mm |

| position precision | ±0.2mm |

| working power | AC 50Hz 220V |

| total power | 1.5Kw |

| whole weight | 780Kg |

| overall dimension(L*W*H) | machine:1500*820*900mm |

| controlling carbine:460X280X720mm |

Product information

QD-350 Microcomputer Controlled High Speed Automatic Segmenting Machine adopts microcomputer controlling , regulate the speed by frequency conversion, photoelectric tracking, step motor controlling fixing length system, material feeding displacement compensation tracking system, automatic counting, alarming, can set output times and so on .

It is with the features of high speed, low power, high precision, stable working, reliable working, full function, easy operation and so on .

The machine is suitable for roll material cutting into fixed length, tracking cutting, and it is an ideal machine of horizontal cutting for label, printed bags, printed film, hot shrink film, paper and undried adhesive products

Sample

|

|

Selected Products

News Center

> Automatic die-cutting machine type

The automatic die-cutting machine is that the paper feeder sends the paper to the designated position of the front gauge and the side gauge through the feeding part,...

> How is the pla paper cup produced by the disposable paper cup manufacturer?

How is the pla paper cup produced by the disposable paper cup manufacturer? It turned out to be done in this way

> The process of making paper cups for hot drinks

The production process of the disposable paper cup cold drink cup is direct printing, die cutting, molding processing, and spraying food wax on the surface of the pa...

> Raw materials for making paper cups

1. In the raw materials for making paper cups, in order to avoid the production of toxic solvents, the national standard stipulates that paper cups should not have p...

GET A QUOTE